By the late 1950s, many physicists and electrical engineers were tinkering with the idea of miniature electronic circuits. Robert Noyce, a California physicist, was one of them. “These attempts [at miniaturization] were largely unsuccessful,” Noyce wrote years later, “but they publicized the demand for miniaturization and the potential rewards for the successful development of some form of microelectronics. A large segment of the technical community was on the lookout for a solution to the problem because it was clear that a ready market awaited the successful inventor.” Noyce’s firm, Fairchild Semiconductor, of Mountain View, California, was one of the companies pursuing a solution. So was Texas Instruments (TI), of Dallas.

In the summer of 1958, Jack Kilby, an engineer for TI, created the first bona fide IC, a circuit known as a phase-shift oscillator (a device that oscillates signals at a given rate). Other ICs followed in rapid succession, and his first patent was filed on 6 February 1959. Exactly one month later, although rumors of Kilby’s work had already swept through the electronics industry, TI proudly announced the invention at a news conference at an industry convention in New York City, proclaiming “the development of a semiconductor solid circuit no larger than a match head.” The trade press was full of the news. Even the popular media carried the story, and TI stock, always a high flier, rose several points. It certainly seemed as though TI, an aggressive, pioneering firm, had made a pivotal breakthrough.

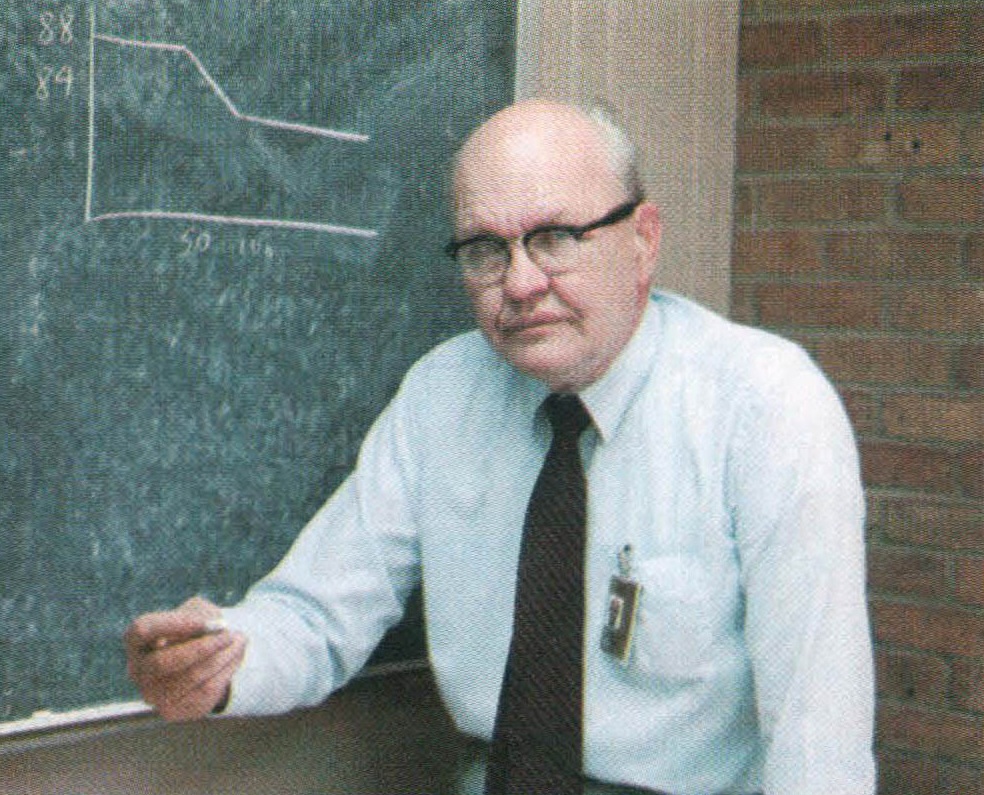

A husky, soft-spoken, serious man, Kilby came to TI in May 1958, after having spent eleven years at Centralab Inc., a large radio and television parts manufacturer in Milwaukee, Wisconsin. (Centralab is a subsidiary of Globe-Union Inc., a major electrical components and equipment maker.) Kilby had grown up in Great Bend, Kansas, where his father, an electrical engineer, was president of the local power company. Like father, like son, Kilby decided to become an engineer. After being turned down by MIT – Kilby’s high school grades were not outstanding – he went to the University of Illinois. Then the United States entered World War II, and Kilby joined the Army. He served with the Office of Strategic Services (the forerunner of the Central Intelligence Agency) in Burma and China, returned to college in 1945, and graduated two years later. Centralab was the only company that offered him a job, and he went to work on silk-screening techniques for printing certain simple electronic components on ceramic wafers.

Centralab was hardly a backwater. The firm had done a lot of research in miniaturization and automation, and Kilby was strongly influenced by its work. During the war, for instance, Centralab had been a subcontractor for the National Bureau of Standards in a project to develop compact and rugged ceramic circuits for proximity fuzes. (It was the Bureau of Standards that sponsored Project Tinkertoy.) After the war, when Kilby was on board, Centralab worked with the Army’s Diamond Ordnance Fuze Lab oratories, in Maryland, to develop ceramic circuits whose components were deposited by photolithography – a technique, pioneered by Bell Labs, that was important to the development of ICs. The company was also one of the earliest producers of transistors; along with TI and several other firms, it bought a transistor manufacturing license from Bell Labs, dispatching Kilby and a colleague to Bell’s 1952 symposium on the invention.

Back at Centralab, Kilby helped set up a small transistor manufacturing line. The components were sold to hearing aid manufacturers, but the operation was only marginally profitable. By the late 1950s, the semiconductor industry was switching from germanium to silicon transistors, which offered several distinct manufacturing and operational advantages. (For example, silicon is much more resistant to heat than germanium.) But Centralab couldn’t afford the substantial equipment and development costs entailed by a switch to silicon; the company was certain to fall irretrievably behind the competition if it didn’t make the move. Armed with years of experience in the physics and manufacturing of transistors, Kilby decided it was time to move on. This time, he received several job offers.

He could not have found a better home than TI, an innovative, aggressive, and highly profitable firm with a knack for transforming the latest technological advances into marketable products. In 1954, in one of its best-known technical coups, TI became the first company to make silicon transistors. It did so only two years after the Bell Labs symposium, and its achievement was all the more impressive in light of the price it put on those transistors: a mere $2.50 each, five to six times less than the going rate for germanium transistors. (That figure was low enough to enable another pioneering firm, Regency, of Indianapolis, Indiana, to produce the first portable transistor radios in 1955.) Like many electronic firms, TI was deeply interested in miniaturization; the Army’s Micromodule Plan had just received its initial funding and TI, always close to the military, wanted a piece of the action.

That was where Kilby fit in. He was assigned to a small research group headed by an engineer named Willis Adcock. Kilby’s duties were undefined, although it was understood that he would work on miniaturization. TI was preparing to submit a micromodule proposal to the Army, and Kilby realized that he probably would be called upon to help the company’s effort. But he was extremely skeptical of the Micromodule Plan – he believed that it was wiser to layout circuits horizontally instead of vertically – and he immediately began searching for a better approach. He explained what happened next:

At that time, radio was still a significant part of the electronics business, and I began to look at the possibility of making an IF strip [an intermediate-frequency amplifier, which is used widely in radios]. I proposed to do this by making all of the components in tubular form, which I think would have been an easier and preferable technique to the flat wafers of the micromodule deal. I spent a few months on this, and built a couple of models that worked. But in looking at the costs, particularly within a semiconductor company, it became apparent that the labor costs were much higher than those at Centralab, and that we really couldn’t afford very much hand assembly….

In those days, TI had a mass vacation policy; that is, they just shut down tight during the first few weeks of July, and anybody who had any vacation time coming took it then. Since I had just started and had no vacation time, I was left pretty much in a deserted plant; so I began to think about the lessons of the IF strip. It became clear that there were some things the semiconductor houses could do very well, and that they had some potent techniques that this IF strip did not make very good use of. I began to cast around for alternatives – and the monolithic [or solid circuit] concept really occurred to me during that two-week vacation period. I had it all written up by the time Willis got back, and I was able to show him sketches that pretty well outlined the idea – and the process sequence showing how to go about building it.

Willis Adcock, Kilby’s boss, was impressed but skeptical. He doubted that it was possible to make a circuit entirely out of discrete semiconductor components, let alone integrated ones. Kilby’s first challenge, then, was to build a circuit out of discretes.